The Role of Software of Modern Control Panels

In today’s fast-paced industrial landscape, software has emerged as the cornerstone of modern control panel functionality. Control panels, once solely dependent on hardware, now rely heavily on software for seamless integration, advanced automation, and precise control. This shift marks a new era in manufacturing and industrial operations, where software-driven control panels enhance efficiency, safety, and adaptability.

Bridging Hardware and Software

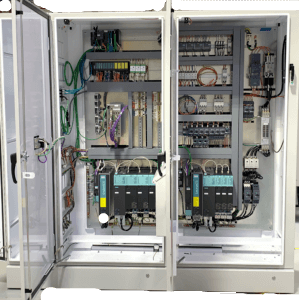

The synergy between hardware and software is central to the operation of control panels. Hardware components, such as switches, relays, and circuit breakers, form the foundation. Software, however, brings intelligence to the system. It enables the hardware to communicate, process data, and execute commands efficiently.

For instance, programmable logic controllers (PLCs) and human-machine interfaces (HMIs) rely on robust software to monitor and control industrial processes. These tools allow operators to visualize system status in real time and make adjustments with ease.

Enhancing Automation

Software in control panels is a driving force behind automation. Automated systems can process vast amounts of data, recognize patterns, and make decisions with minimal human intervention. This reduces errors and boosts productivity.

Consider the role of software in automated assembly lines. It ensures that every stage of production runs smoothly by synchronizing the actions of machines, conveyors, and sensors. With precise programming, control panels can respond to dynamic production requirements, maintaining high efficiency under varying conditions.

Improving Safety Standards

Safety is a top priority in any industrial setting, and modern control panel software plays a critical role in achieving it. Through intelligent programming, software can detect anomalies, trigger alarms, and initiate emergency shutdowns when necessary.

For example, control panel software in hazardous environments often includes fail-safe mechanisms. These systems continuously monitor conditions and respond to potential risks before they escalate. This proactive approach minimizes downtime and protects personnel and equipment.

Streamlining Maintenance and Diagnostics

Software also simplifies maintenance and troubleshooting processes. Many modern control panels are equipped with diagnostic tools that analyze system performance and identify potential issues. These tools often come with predictive maintenance features, alerting technicians to address problems before they cause failures.

Remote monitoring is another benefit enabled by software. Operators can access control panels from virtually anywhere, using connected devices to check status, perform updates, or resolve issues without being on-site.

Adapting to Emerging Technologies

The evolution of software in control panels ensures adaptability to emerging technologies. Trends such as artificial intelligence (AI) and the Internet of Things (IoT) are becoming integral to industrial operations. Control panel software is evolving to integrate these technologies, creating smarter and more interconnected systems.

For instance, IoT-enabled control panels collect and share data with other devices in the network. This connectivity supports better decision-making and enhances overall operational efficiency. AI algorithms, when integrated with control panel software, can optimize processes, predict outcomes, and provide actionable insights.

User-Friendly Interfaces

A key advantage of modern software is its focus on user experience. Intuitive HMIs enable operators to interact with control panels effortlessly. Graphical displays, touchscreens, and customizable dashboards make it easier to monitor processes, execute commands, and understand system performance.

This accessibility reduces the learning curve for new operators and enhances productivity. Even in complex systems, well-designed software ensures that users can quickly grasp and navigate essential functions.

The Future of Control Panel Software

As technology advances, control panel software will continue to evolve. Features like real-time analytics, machine learning, and augmented reality are expected to become commonplace. These innovations will further enhance the capabilities of control panels, driving efficiency, adaptability, and innovation across industries.

In conclusion, software has transformed control panels from basic hardware assemblies into sophisticated systems that power modern industries. By enabling automation, enhancing safety, and adapting to new technologies, software ensures that control panels remain at the forefront of industrial innovation. At MIS Controls, we embrace these advancements to deliver cutting-edge solutions tailored to your needs.