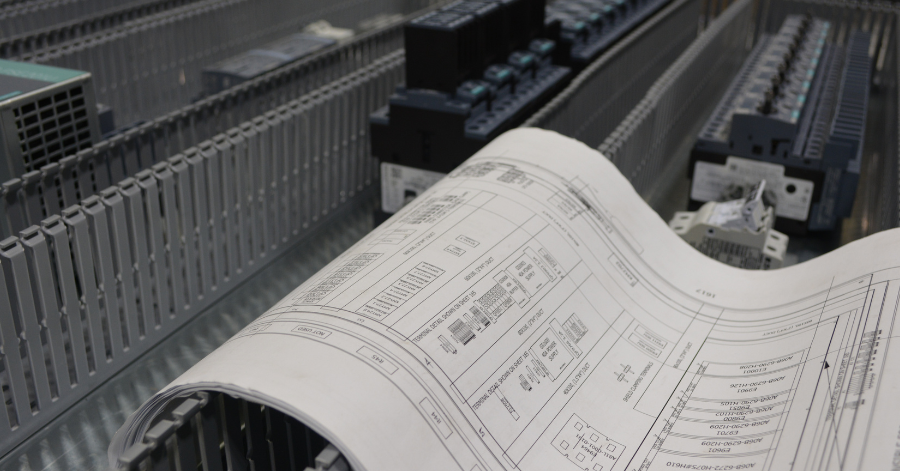

The Art of Customization: Tailoring Control Panels to Industry Needs

In the dynamic and diverse world of industrial operations, one size rarely fits all. Every industry, and indeed every company within those industries, has unique requirements and challenges. This is where the art of customization comes into play, particularly in the realm of control panels. Tailoring control panels to specific industry needs ensures optimal performance, efficiency, and reliability. At MIS Controls, we understand the importance of custom control panels and have honed our expertise to deliver bespoke solutions that meet the precise demands of our clients. Here’s a closer look at how we master the art of customization.

Understanding Industry-Specific Requirements

In-Depth Analysis: The first step in customization is understanding the unique needs of each industry. This involves a thorough analysis of operational processes, environmental conditions, regulatory requirements, and technological demands. Our team engages closely with clients to gather detailed insights into their specific challenges and goals.

Example: In the oil and gas industry, control panels must withstand harsh environmental conditions, including extreme temperatures and corrosive elements. We design robust, weatherproof panels with advanced monitoring capabilities to ensure reliability and safety in such demanding environments.

Designing for Precision and Performance

Tailored Solutions: Customization is about precision. By tailoring control panel designs to the exact specifications of each application, we ensure that our solutions deliver optimal performance. This involves selecting the right components, configuring the layout for ease of use, and incorporating features that enhance functionality.

Example: For the pharmaceutical industry, where precision and hygiene are paramount, we design control panels with stainless steel enclosures, touch-screen interfaces for easy operation, and advanced data logging for regulatory compliance. These panels ensure that production processes are controlled with the utmost accuracy and cleanliness.

Incorporating Advanced Technologies

Staying Cutting-Edge: Leveraging the latest technologies is a crucial aspect of customization. At MIS Controls, we integrate advanced technologies such as IoT, AI, and machine learning into our control panels. These technologies provide enhanced capabilities, from real-time monitoring and predictive maintenance to automated decision-making and process optimization.

Example: In the manufacturing sector, incorporating IoT-enabled sensors in control panels allows for real-time data collection and remote monitoring. This not only improves operational efficiency but also enables predictive maintenance, reducing downtime and extending equipment life.

Flexibility and Scalability

Adapting to Growth: Industries evolve, and so do their needs. Custom control panels from MIS Controls are designed with flexibility and scalability in mind, allowing businesses to adapt and grow without the need for extensive reconfiguration. This forward-thinking approach ensures that our solutions remain relevant as industry requirements change.

Example: In the renewable energy sector, control panels must adapt to varying energy outputs and integration of new technologies. Our scalable designs enable easy upgrades and expansions, ensuring that the control systems can grow with the industry’s advancements.

Compliance with Industry Standards

Ensuring Adherence: Every industry is governed by specific standards and regulations. Ensuring compliance is critical, and our customized control panels are designed to meet or exceed these regulatory requirements. This not only ensures legal compliance but also enhances safety and reliability.

Example: For the food and beverage industry, our control panels comply with stringent hygiene and safety standards. Features such as easy-to-clean surfaces, sealed enclosures, and compliance with HACCP guidelines ensure that our panels support safe and sanitary operations.

User-Centric Design

Ease of Use: A key element of customization is designing control panels that are user-friendly and intuitive. This involves considering the needs and preferences of the end-users, from operators to maintenance personnel. Our designs prioritize ease of use, with clear interfaces, logical layouts, and accessible controls.

Example: In the automotive industry, where quick and efficient operations are essential, we design control panels with ergonomic layouts, intuitive touch screens, and customizable interfaces. These features enable operators to control complex processes with minimal training and maximum efficiency.

Comprehensive Support and Service

End-to-End Solutions: Customization doesn’t end with the delivery of the control panel. At MIS Controls, we provide comprehensive support throughout the lifecycle of our solutions. This includes installation, training, maintenance, and upgrades, ensuring that our clients get the most out of their customized control panels.

Example: For a large-scale industrial plant, we offer ongoing support and regular maintenance services to ensure that the control panels operate flawlessly. Our team provides training to the plant’s personnel, ensuring they are fully equipped to utilize the control panels effectively.

Conclusion

The art of customization is about more than just creating a control panel that fits; it’s about crafting a solution that enhances efficiency, reliability, and performance for each unique application. At MIS Controls, we excel in understanding the distinct needs of various industries and delivering tailored solutions that exceed expectations. By focusing on precision, incorporating advanced technologies, ensuring compliance, and providing comprehensive support, we master the art of customization, helping our clients achieve their operational goals with bespoke control panels that truly meet their needs.