Future Trends in Custom Control Panel Technology

In an increasingly digital world, custom control panel technology is advancing at a rapid pace. Manufacturers are striving to meet the demands of automation, connectivity, and sustainability. These trends are shaping the future of control panel solutions across industries, from manufacturing to healthcare and beyond. Let’s explore the key advancements that are transforming custom control panels and their impact on modern businesses.

1. Enhanced Connectivity through IoT Integration

The Internet of Things (IoT) is revolutionizing custom control panel technology. Modern control panels are designed to support smart devices, enabling seamless communication across equipment and systems. This connectivity allows real-time monitoring and diagnostics, reducing downtime and increasing operational efficiency. For example, predictive maintenance systems powered by IoT sensors can alert users to potential failures before they occur.

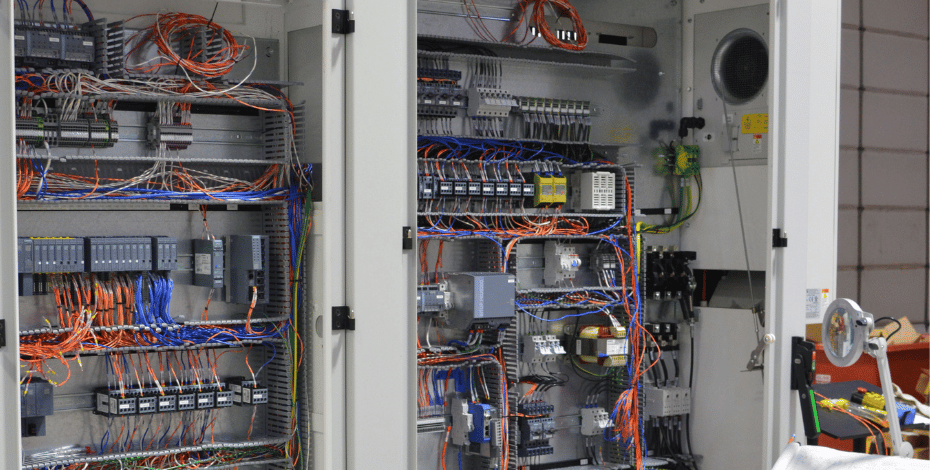

2. Modular and Scalable Designs

Customization is no longer about creating a one-size-fits-all solution. The trend is shifting toward modular designs that offer flexibility. Modular control panels allow businesses to scale their operations by adding or removing components as needed. This approach reduces upfront costs while providing room for growth. Industries with evolving needs, such as renewable energy or automotive manufacturing, benefit significantly from this adaptability.

3. Integration of AI and Machine Learning

Artificial intelligence (AI) and machine learning are enhancing the functionality of control panels. These technologies enable systems to learn from data, optimize performance, and adapt to changes in real-time. For example, machine learning algorithms can analyze usage patterns and suggest energy-saving measures. AI-powered interfaces also simplify complex tasks, making control panels more user-friendly.

4. Focus on Energy Efficiency and Sustainability

Sustainability is becoming a top priority in control panel design. Manufacturers are incorporating energy-efficient components and materials to reduce environmental impact. Smart energy management systems within control panels can monitor and optimize power consumption. These innovations align with global sustainability goals, helping businesses reduce costs and meet regulatory requirements.

5. Improved User Interfaces

Modern control panels feature intuitive user interfaces (UIs) that enhance usability. Touchscreens, customizable dashboards, and voice-activated controls are becoming standard. These advancements simplify operation and minimize the learning curve for new users. Additionally, augmented reality (AR) tools are being integrated for training and troubleshooting, providing visual guides directly on the control panel screen.

6. Advanced Cybersecurity Measures

As control panels become more connected, cybersecurity is critical. Cyberattacks can disrupt operations and compromise sensitive data. Future control panel designs will feature robust security protocols, including encryption, multi-factor authentication, and intrusion detection systems. These measures protect against evolving cyber threats and ensure system integrity.

7. Compact and Lightweight Designs

Space constraints in modern facilities are driving the demand for compact control panels. Engineers are developing lightweight solutions without compromising performance. These designs are ideal for industries like aerospace and transportation, where space and weight are at a premium.

8. Customization for Industry-Specific Needs

Different industries have unique requirements, and future control panels will cater to these needs more effectively. For example, panels in the pharmaceutical sector may include features for precise temperature and humidity control. Similarly, control panels for the oil and gas industry will focus on durability and safety in harsh environments. Tailored solutions ensure optimal performance and compliance with industry standards.

9. Wireless Technologies

Wires are becoming a thing of the past as wireless technologies gain traction. Wireless control panels offer greater flexibility in installation and operation. They also reduce maintenance costs by eliminating physical connections that can wear out over time. Wireless solutions are particularly valuable in remote or hazardous locations, where traditional wiring is impractical.

10. Increased Emphasis on Data Analytics

Control panels are becoming hubs for data collection and analysis. By integrating advanced analytics tools, businesses can gain valuable insights into their operations. These insights enable better decision-making, process optimization, and predictive maintenance. As data analytics evolves, control panels will play an even greater role in driving efficiency and innovation.

Conclusion

The future of custom control panel technology is exciting and full of potential. Trends like IoT integration, AI, and modular designs are shaping smarter, more efficient solutions. As industries continue to evolve, so will the demand for innovative control panel technologies that meet specific needs. By staying ahead of these trends, businesses can unlock new opportunities and remain competitive in a dynamic marketplace.

At MIS Controls, we’re committed to delivering cutting-edge control panel solutions that align with the latest trends. Contact us today to learn how we can help you future-proof your operations.